06

06

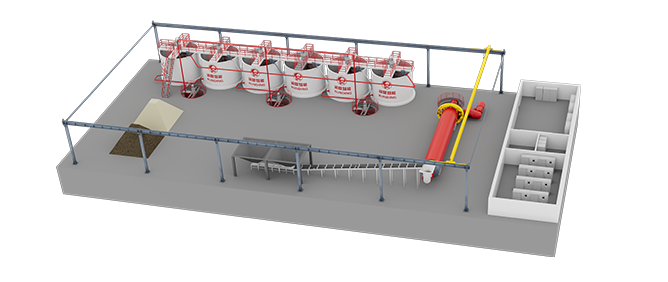

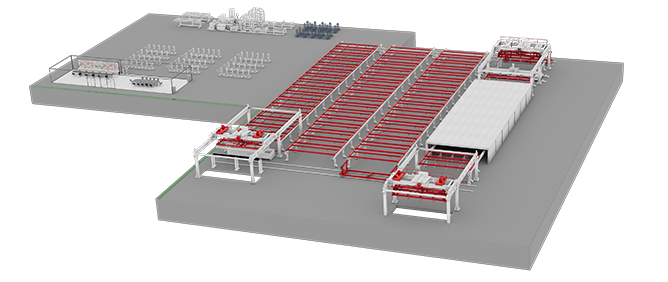

Rigorous project planning

Runding has a very rich experience in the planning of aerated concrete

plant projects, based on the local aerated market capacity, aerated product

classification, raw materials, competitive product structure, etc. Give

professional and reliable guidance and suggestions on project positioning

planning, product positioning planning, plant layout planning, equipment

selection planning, electrical control planning, production timing planning,

and worker configuration planning to meet your project needs and reduce

your investment risk as much as possible.

+

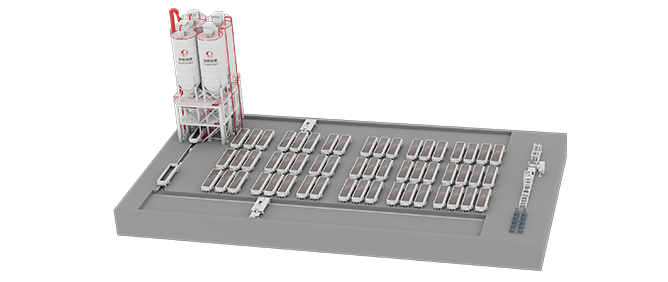

Rigorous project planning

Runding has a very rich experience in the planning of aerated concrete

plant projects, based on the local aerated market capacity, aerated product

classification, raw materials, competitive product structure, etc. Give

professional and reliable guidance and suggestions on project positioning

planning, product positioning planning, plant layout planning, equipment

selection planning, electrical control planning, production timing planning,

and worker configuration planning to meet your project needs and reduce

your investment risk as much as possible.

-