1. Selection of green raw materials: Exploring the potential of renewable and industrial solid waste

1.1 Renewability of siliceous and calcareous materials

The main raw materials for AAC structural parts processing include siliceous materials (such as silica sand) and calcareous materials (such as lime and cement). The selection of these raw materials is crucial to the performance and environmental attributes of the product. As a mineral resource widely found in nature, the mining and utilization of silica sand is relatively environmentally friendly, and in some areas, the sustainable utilization of silica sand resources can be achieved through reasonable mining planning and reclamation measures. In terms of calcareous materials, although the production process of cement will produce certain carbon emissions, in recent years, with the widespread application of low-carbon cement and mineral admixtures (such as fly ash, slag, etc.), the environmental performance of the cement industry has also been gradually improved.

1.2 Recycling of industrial solid waste

In the exploration of green raw materials, AAC structural parts processing manufacturers pay particular attention to the recycling of industrial solid waste. Industrial wastes such as fly ash, slag, and desulfurized gypsum can be used as one of the raw materials for AAC products after specific treatment processes. The utilization of these wastes not only reduces the exploitation of primary resources, but also solves the problem of industrial waste disposal, achieving the maximum utilization of resources and minimizing the burden on the environment. Fly ash, as a waste of coal-fired power plants, contains a large amount of active silicon and aluminum components, and is an ideal substitute for siliceous raw materials in AAC products. Through scientific proportioning and process optimization, the addition of fly ash can not only improve the performance of AAC products, but also significantly reduce production costs.

2. Waste utilization: achieving closed-loop management of resources

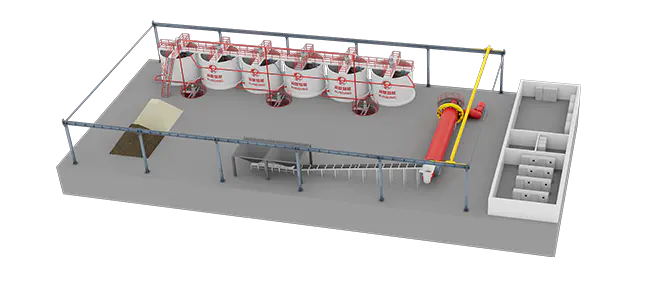

2.1 Waste recycling in the production process

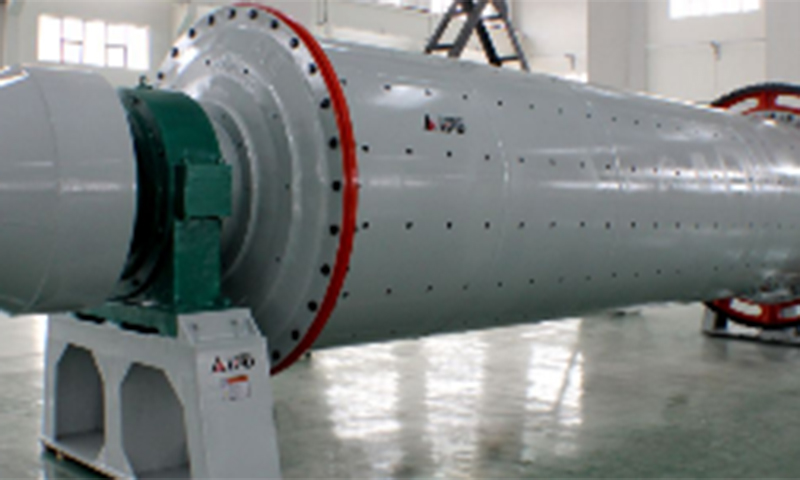

A certain amount of wastewater, waste materials and tail gas will be generated during the processing of AAC structural parts. The effective recycling and utilization of these wastes is the key to achieving closed-loop management of resources. In terms of wastewater, harmful substances in wastewater can be removed through treatment processes such as sedimentation, filtration, and neutralization to meet emission standards or reuse standards. Some manufacturers also use the heat in wastewater for heat recovery, further improving energy efficiency. In terms of waste materials, scraps and unqualified products generated during the cutting process can be used as a supplement to raw materials and re-entered into the production process after crushing, screening and other treatments. In terms of tail gas, the tail gas discharged from the autoclave contains a certain amount of heat and water vapor. Through condensation recovery technology, the moisture and heat in the tail gas can be recycled and utilized to reduce energy consumption and wastewater discharge.

2.2 Practice of circular economy model

In terms of waste utilization, AAC structural parts processing manufacturers are also actively exploring circular economy models. Through cooperation with upstream and downstream enterprises, an industrial symbiosis chain is formed to realize the resource utilization of waste. Cooperate with coal-fired power plants to use fly ash generated by power plants as raw materials; cooperate with construction waste treatment companies to crush construction waste as aggregate for AAC products; cooperate with cement companies to recycle and reuse discarded cement packaging bags, etc. These cooperation models not only reduce waste emissions, but also promote the coordinated development of upstream and downstream enterprises in the industrial chain, achieving a win-win situation of economic and environmental benefits.

3. Achievements and challenges of green raw materials and waste utilization

For AAC structural parts processing manufacturers, the selection of green raw materials and the effective utilization of waste not only improve the environmental performance and market competitiveness of products, but also bring significant economic and social benefits. There are also some challenges in the implementation process. Such as the instability of raw material sources, bottlenecks in waste treatment technology, pressure on cost control, etc. Therefore, manufacturers need to continuously innovate and optimize production processes, strengthen cooperation with scientific research institutions and upstream and downstream companies, and jointly promote the research and development and application of green raw materials and waste utilization technologies to achieve a more environmentally friendly, efficient and sustainable production method.