1、 Regular inspection and cleaning

1. Cleaning is the foundation

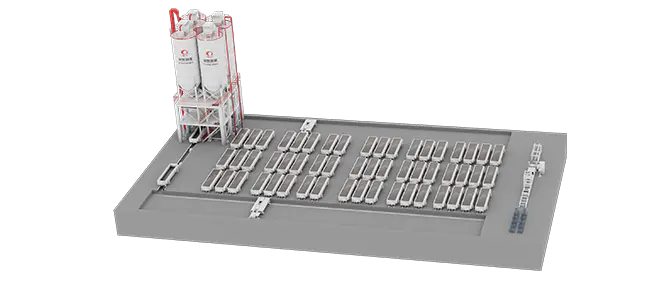

Regularly cleaning the various components of the light weight block machine is a fundamental step in maintaining the normal operation of the equipment. Especially components such as vibration tables, molds, conveying systems, and hydraulic systems are prone to accumulating dust and impurities. If not cleaned properly, these dirt and residues may affect the operation of the machine and even cause mechanical failure.

Cleaning the vibration table: The vibration table is an important component in the light weight block machine, which functions to fully compact the concrete through vibration. If the surface of the vibration table is covered with impurities, it will affect the vibration effect and lead to unstable product quality. Therefore, it is necessary to regularly inspect the vibration table and remove dust and sediment from its surface.

Cleaning the mold: The mold is a key component that determines the size and appearance quality of the blocks. If too much concrete residue adheres to the surface of the mold, it may cause dimensional errors in the blocks and even damage to the mold. Regularly cleaning the mold to ensure its cleanliness and flatness can prevent such situations from occurring.

2. Check the cleanliness of each component

The conveying system and hydraulic system of the lightweight block machine also need to be regularly cleaned and inspected. If there are impurities or corrosive substances in these systems, it may affect their transmission efficiency and stability, resulting in the system not working smoothly. Therefore, operators should conduct a comprehensive inspection once a week or month and clean relevant components such as pipelines, valves, and oil cylinders.

2、 Maintenance of lubrication system

1. Regularly replace lubricating oil

The function of lubricating oil is to reduce friction between various moving parts and prevent excessive wear. During the operation of the light weight block machine, the lubricating oil will gradually lose its original lubricating effect, so it needs to be replaced regularly. Usually, it is recommended to check the condition of the lubricating oil every three months and replace it if necessary.

2. Selection of lubricating oil

Choosing the appropriate lubricating oil is crucial for extending the lifespan of equipment. Different mechanical components require different types of lubricating oil. For example, hydraulic system oil and transmission system oil have different requirements. Using appropriate lubricating oil can not only reduce the wear of mechanical components, but also improve the efficiency of equipment operation.

3. Check the lubricating oil pipeline

Lubricating oil pipelines are prone to blockage or damage due to prolonged use, resulting in the inability of lubricating oil to flow normally. Regularly inspecting the lubricating oil pipeline to ensure its unobstructed flow can effectively guarantee the lubrication effect of mechanical components.

3、 Maintenance of hydraulic system

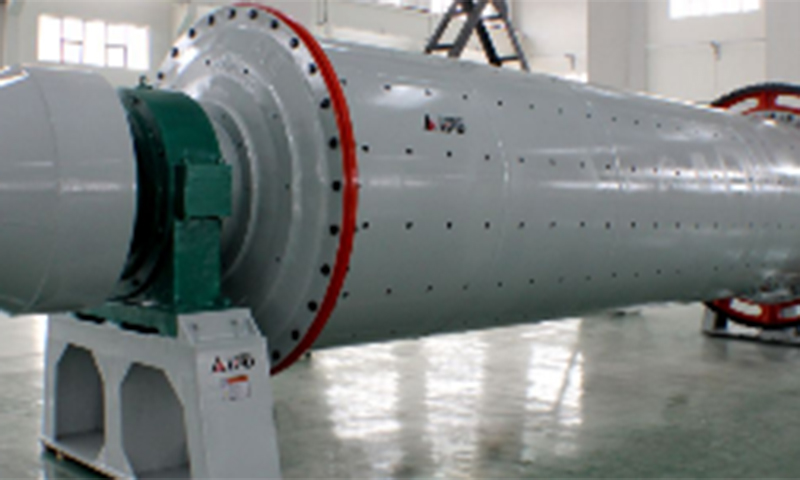

The hydraulic system is one of the core driving parts of the light weight block machine, which directly affects the machine's work efficiency and operational accuracy. Hydraulic system failure can cause unstable machine operation, affect production efficiency, and even lead to shutdown. Therefore, maintenance of the hydraulic system is particularly important.

1. Check the hydraulic oil

The quality and quantity of hydraulic oil directly affect the normal operation of hydraulic systems. Operators need to regularly check the level and quality of hydraulic oil. If the hydraulic oil is contaminated, aged, or has a low oil level, it should be replaced promptly and new oil should be added.

2. Replace the hydraulic oil filter element

Hydraulic oil filter element is used to filter impurities in oil and prevent wear of internal components of the system. After prolonged use, the filter element may become clogged or damaged, reducing its filtration efficiency. It is recommended to replace the hydraulic oil filter element at regular intervals to maintain the cleanliness and efficient operation of the hydraulic system.

3. Hydraulic pipeline inspection

Once hydraulic pipelines leak or break, it may cause a decrease in hydraulic system pressure, affecting equipment operation. Therefore, regularly check the sealing and pressure resistance of hydraulic pipelines to ensure that there are no leaks.

4、 Maintenance of electrical system

The normal operation of the electrical system directly affects the automation level and work efficiency of the lightweight block machine. Regular inspection of the electrical system can prevent many shutdowns and production accidents caused by electrical failures.

1. Check the electrical control box

The electrical control box of the lightweight block machine needs to be regularly inspected for loose, corroded, or damaged wires, electrical switches, and connectors inside. Especially in humid environments, the electrical control box is prone to short circuits or malfunctions, so it is necessary to ensure that the electrical control box is dry and clean.

2. Maintain the electric motor

Electric motors are important power sources for driving various components of lightweight block making machines. Regularly inspect the working condition of the motor, clean the dust on the surface of the motor, and check whether there is wear on the motor's brushes, bearings, and other components. Lubrication and replacement should be carried out as necessary to ensure the long-term stable operation of the motor.

5、 Maintenance of molds and accessories

The molds and accessories of lightweight block making machines directly affect the appearance and size of the blocks, so maintenance of these components is also key to ensuring long-term efficient operation of the equipment.

1. Inspection and replacement of molds

As production time increases, mold wear is inevitable. After the mold wears or deforms, it will lead to a decrease in the quality of the blocks, so it is necessary to regularly check the wear of the mold. If cracks or deformations are found in the mold, it should be replaced or repaired in a timely manner.

2. Regularly replace vulnerable parts

Some components in the lightweight block machine are vulnerable parts, such as sealing rings, transmission belts, etc. If these components are used for a long time without replacement, they may cause equipment failure. Therefore, operators need to regularly check the wear and tear of these components and make necessary replacements.

6、 Training and management of operators

The maintenance of equipment not only relies on technical means, but also on the operation and management of operators, which are equally crucial. Professional operators are able to identify and address potential issues when using lightweight block machines, effectively avoiding equipment failures.

1. Regularly train operators

Regularly train operators on equipment usage and maintenance to ensure they have the correct operating skills and maintenance knowledge. This can reduce malfunctions caused by improper operation and extend the service life of the equipment.

2. Strengthen management system

Establish a sound equipment maintenance management system, requiring operators to regularly inspect and record the operation of equipment, as well as various maintenance work. This not only helps to identify problems, but also enables timely measures to be taken to prevent malfunctions from occurring.