AAC Block Production Line occupies an important position in the building materials manufacturing industry, but its energy consumption and environmental pollution issues cannot be ignored. In order to achieve sustainable development, it is crucial to optimize the production process to reduce the energy consumption and environmental pollution of AAC Block Production Line.

1. Optimize equipment configuration and operation

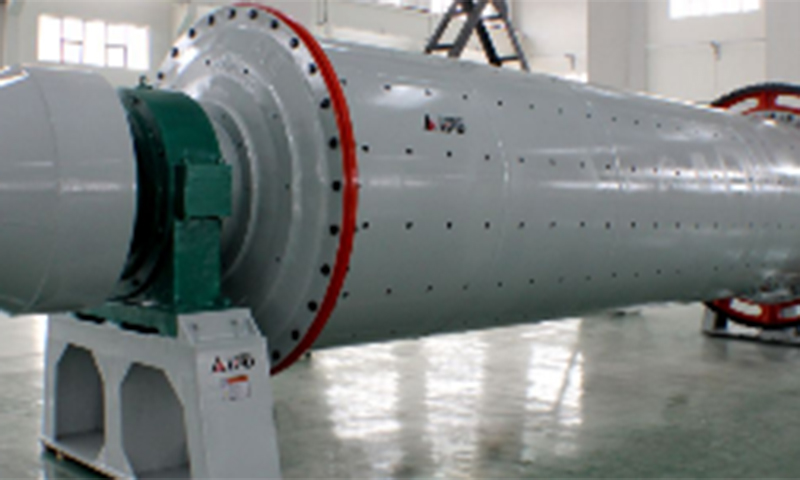

Select high-efficiency and energy-saving equipment: In the AAC Block production line, high-efficiency and energy-saving equipment should be selected, such as high-efficiency motors, energy-saving boilers and compressors. These equipment consume less energy during operation, which helps to reduce overall energy consumption.

Regular maintenance and overhaul of equipment: Regularly maintain and overhaul the equipment to ensure that the equipment is in the best operating state. This can not only reduce energy waste caused by equipment failure, but also extend the service life of the equipment.

Optimize equipment operating parameters: By adjusting the operating parameters of the equipment, such as temperature, pressure, flow, etc., the equipment can be operated in the best state, thereby reducing energy consumption.

2. Improve the production process

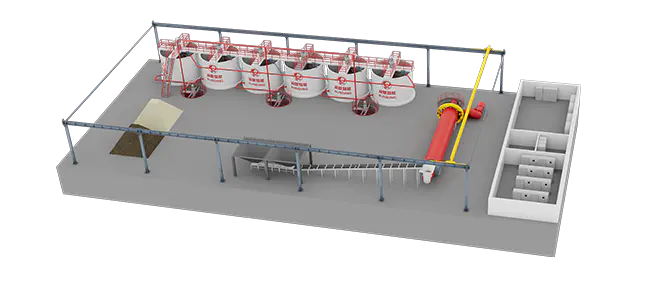

Streamline the process links: Analyze the existing production process, remove unnecessary links and steps, and reduce energy consumption. For example, by optimizing the material conveying method and path, the residence time of materials in the process and the transportation energy consumption can be reduced.

Improve the degree of automation: Introduce automated equipment and control systems to reduce manual intervention and operation, reduce energy consumption and energy waste caused by human factors. Automated production can not only improve production efficiency, but also ensure the stability of product quality.

Optimize heating and cooling processes: In the production process of AAC Block Production Line, heating and cooling links are the main part of energy consumption. By optimizing these processes, such as adopting more efficient heating methods and more reasonable cooling systems, energy consumption can be significantly reduced.

3. Implement energy monitoring and management

Establish an energy monitoring system: Install an energy monitoring system to monitor and analyze energy consumption in the production process in real time. This helps to timely discover and solve energy waste problems and provide data support for optimizing production processes.

Conduct energy audits regularly: Through energy audits, understand the energy consumption status of the enterprise, find out energy-saving potential, and propose improvement measures. This helps enterprises to continuously improve production processes and reduce energy consumption.

4. Promote green technologies and materials

Use clean energy: In AAC Block Production Line, clean energy is used to replace traditional energy as much as possible, such as solar energy and wind energy. This can not only reduce dependence on traditional energy, but also reduce greenhouse gas emissions.

Promote green materials: In the production process, give priority to environmentally friendly materials to replace highly polluting raw materials to reduce the use and emission of harmful substances. At the same time, reduce material loss through refined management to achieve resource conservation and recycling.

V. Strengthen environmental protection measures and supervision

Improve the wastewater treatment system: pre-treat and discharge the wastewater generated in the production process in compliance with standards. By installing efficient wastewater treatment equipment, ensure that harmful substances in the wastewater are effectively removed and reduce pollution to the environment.

Strengthen waste gas treatment: collect and treat the waste gas generated in the production line, and use advanced waste gas treatment equipment to remove harmful substances in the waste gas. At the same time, establish a waste gas monitoring and management system to ensure that waste gas emissions meet standards.

Strengthen environmental supervision: strictly implement relevant laws and regulations, and promote the pollution permit system and total control system. By strengthening environmental supervision and law enforcement, enterprises are encouraged to take proactive measures to reduce energy consumption and environmental pollution.

Through efforts in optimizing equipment configuration and operation, improving production process, implementing energy monitoring and management, promoting green technology and materials, and strengthening environmental protection measures and supervision, the energy consumption and environmental pollution of AAC Block Production Line can be significantly reduced. This will not only help improve the economic benefits and market competitiveness of enterprises, but also contribute to the realization of sustainable development goals.