As an important equipment in the field of building materials manufacturing, the performance and efficiency of lightweight block machines are directly related to the production capacity and product quality of the entire production line. The traditional manual operation mode is not only inefficient, but also difficult to ensure the consistency and precision of the product. With the rapid development of intelligent manufacturing and automation technology, this industry has gradually moved towards an intelligent, automated and efficient production mode.

1. Intelligent manufacturing: improving production efficiency and quality

The core of intelligent manufacturing lies in the deep integration of information technology, automation technology and artificial intelligence technology to realize the intelligentization, networking and digitalization of the production process. In the lightweight block machine industry, the application of intelligent manufacturing is mainly reflected in the following aspects:

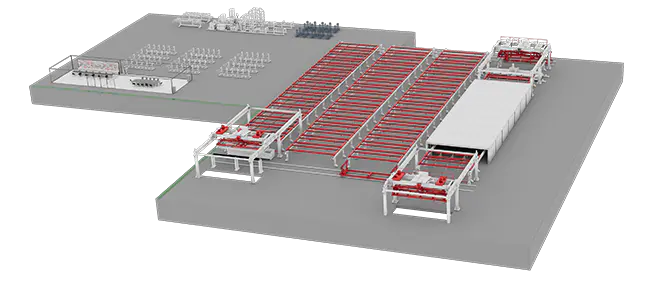

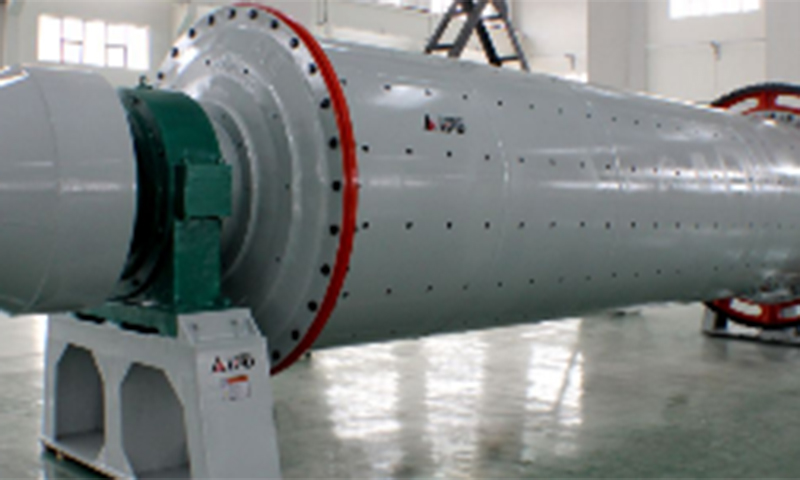

Automated production line: By introducing a highly automated production line, the lightweight block machine can realize the automation of the entire process from raw material input to finished product output. Robots and automated equipment have replaced traditional manual operations, which not only improves production efficiency, but also greatly reduces the human error rate. This continuous 24-hour uninterrupted working mode further improves production capacity and meets the market demand for efficient and high-quality products.

Digital monitoring and management: The intelligent manufacturing system can collect production data in real time and remotely monitor and debug the equipment. Through data analysis, enterprises can promptly discover and solve problems in the production process, optimize production plans, and improve production efficiency. At the same time, the digital management system can also achieve traceability of the production process to ensure that product quality meets standards.

Personalized customization: Intelligent manufacturing technology also helps enterprises achieve personalized customized production. Through modular design, flexible production lines and other technologies, enterprises can quickly adjust production parameters and molds according to the specific needs of customers to produce products that meet customer requirements. This personalized customized production model not only meets the diversified needs of the market, but also improves the market competitiveness of enterprises.

2. Automation technology: reducing costs and improving flexibility

The application of automation technology in the lightweight block machine industry not only improves production efficiency, but also significantly reduces production costs. Specifically manifested in the following aspects:

Reduce labor costs: Automation technology reduces dependence on labor and reduces labor costs. At the same time, by optimizing the production process, the work intensity of workers is reduced and work efficiency is improved.

Reduce waste: Automation technology can accurately control the amount and ratio of raw materials and reduce the waste of raw materials. At the same time, by optimizing the production process, energy consumption and waste emissions are reduced, and green production is achieved.

Improve flexibility: Automation technology enables lightweight block machines to easily respond to market changes. By quickly adjusting production parameters and molds, enterprises can flexibly produce products of different specifications and models to meet the diverse needs of the market. This flexibility not only improves the market competitiveness of enterprises, but also brings more business opportunities to enterprises.

3. The integration of intelligent manufacturing and automation technology

The integration of intelligent manufacturing and automation technology has brought many advantages to the lightweight block machine industry. This integration not only improves production efficiency and reduces costs, but also realizes personalized customization and refined management. It is specifically manifested in the following aspects:

Efficient productivity: The combination of intelligent manufacturing and automation technology realizes the digitization and intelligence of the production process. This efficient production method not only shortens the time to market, but also reduces costs, bringing greater profit space for enterprises.

Excellent quality: Through intelligent manufacturing and automation technology, enterprises can realize real-time monitoring and data analysis of the production process. This refined management method helps to discover potential problems and solve them in a timely manner, improving product quality and reliability.

Personalized customization: The integration of intelligent manufacturing and automation technology enables enterprises to easily realize personalized customized production. Through technologies such as modular design and flexible production lines, companies can quickly adjust product lines according to customer needs to meet the diverse needs of the market.

Sustainable development: Intelligent manufacturing and automation technologies help achieve green production and energy conservation and emission reduction. By optimizing production processes and resource allocation, companies can reduce energy consumption and waste emissions and improve their sustainable development capabilities.