In the building materials industry, light weight block machines are gradually becoming an important force in promoting the green transformation of the industry due to their high efficiency, environmental protection and energy saving characteristics. With the continuous innovation and upgrading of technology, the application prospects of lightweight block machines in the building materials industry are becoming increasingly broad, injecting new vitality into the sustainable development of the construction industry.

Technological innovation and upgrading: the core competitiveness of lightweight block machines

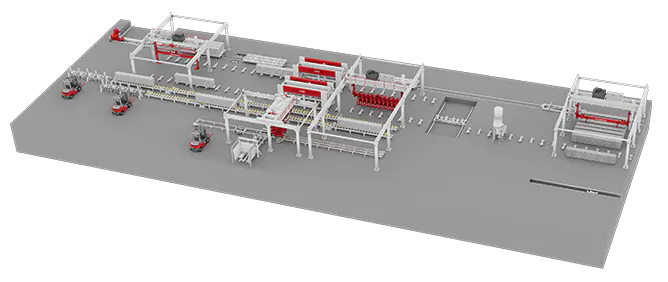

In recent years, light weight block machine technology has experienced rapid development. Traditional block making machines often have problems such as high energy consumption, low efficiency, and unstable product quality during the production process. However, with the advancement of science and technology, the new lightweight block machine adopts advanced technical means to achieve automatic control of the entire process from raw material proportioning, mixing, forming and pressing to curing and drying. This not only greatly improves production efficiency, but also significantly improves product quality, making lightweight blocks more competitive in the market.

In terms of technological innovation, the light weight block machine introduces an intelligent control system. Through advanced equipment such as sensors and PLC programmable controllers, real-time monitoring and precise control of the production process are achieved. This intelligent production method not only improves production accuracy, but also reduces energy consumption and labor costs, bringing significant economic benefits to the enterprise.

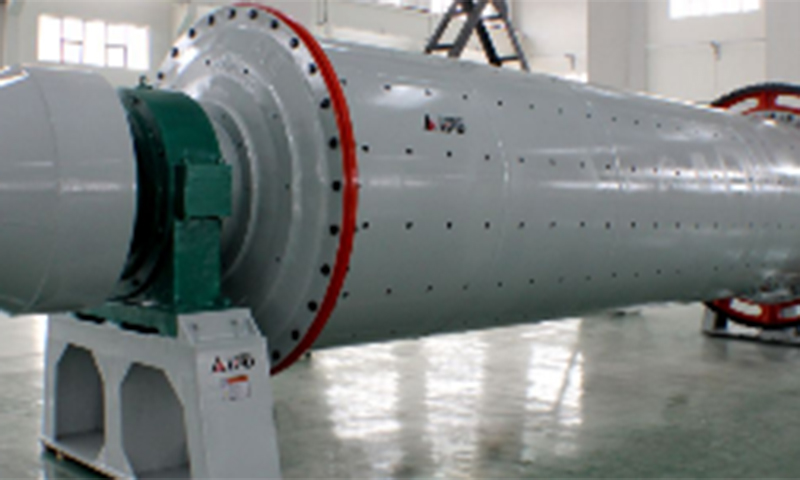

The light weight block machine has also made new breakthroughs in material selection. Traditional block making machines mainly use raw materials such as cement and sand, while new lightweight block making machines begin to use a large amount of industrial waste such as fly ash, slag, and gangue as raw materials. After special treatment, these waste materials can not only produce lightweight blocks with performance, but also realize the recycling of resources and reduce environmental pollution.

Broad application prospects: lightweight block machines lead the green transformation of the building materials industry

The lightweight blocks produced by the lightweight block machine have the advantages of light weight, high strength, good thermal insulation effect, and good sound insulation performance, so they have wide application prospects in the construction industry.

In the field of construction, lightweight blocks can be used as wall materials, thermal insulation materials, etc. to provide excellent performance and comfortable environment for buildings. Because lightweight blocks have good thermal insulation properties, they can significantly reduce the energy consumption of the building and improve the energy-saving efficiency of the building. At the same time, the light weight of lightweight blocks can reduce the weight of the building and reduce the bearing capacity requirements of the foundation, thus saving construction costs.

The light weight block machine is also suitable for home decoration and house repair fields. Because the lightweight blocks are easy to cut and install, they can meet the needs of different customers and achieve personalized customization. At the same time, the environmental performance and aesthetics of lightweight blocks have also been widely recognized by consumers, making them a popular choice for home decoration and house repair.

With the increase of global environmental awareness and the strengthening of government environmental protection policies, the application prospects of lightweight block machines in the building materials industry will be broader. In the future, lightweight block machines will pay more attention to the development direction of green, intelligent and customized. Achieve green production by using more environmentally friendly raw materials, optimizing production processes, and improving production efficiency; realize automation and remote monitoring of the production process by introducing intelligent control systems and artificial intelligence technology; and provide flexible customized services to meet different needs. Customers’ individual needs.

The light weight block machine is the green transformation of the building materials industry with its high efficiency, environmental protection and energy saving characteristics. With the continuous innovation and upgrading of technology, lightweight block machines will play a more important role in the future construction industry and contribute more to the sustainable development of the construction industry.