1. Lightweight materials reduce waste during transportation

Traditional building materials, such as traditional concrete, bricks, etc., are usually heavy, which increases energy consumption and carbon emissions during transportation and construction. AAC blocks, as a lightweight building material, have a density of about 1/3 of that of traditional concrete blocks. Due to their lightweight characteristics, AAC blocks reduce the burden on transportation vehicles during transportation, thereby reducing energy consumption and related carbon emissions. The use of lightweight materials can effectively reduce losses during transportation and handling.

In construction, the light weight of AAC blocks makes handling and installation more convenient and quick, reducing the physical labor of on-site personnel and the risk of material handling damage. The lightweight nature of this material not only helps to reduce the deadweight of the building structure, but also reduces the waste generated by material handling and stacking at the construction site, especially in some urban high-rise buildings or small construction sites, reducing space waste and construction waste during construction.

2. High-precision manufacturing reduces construction waste

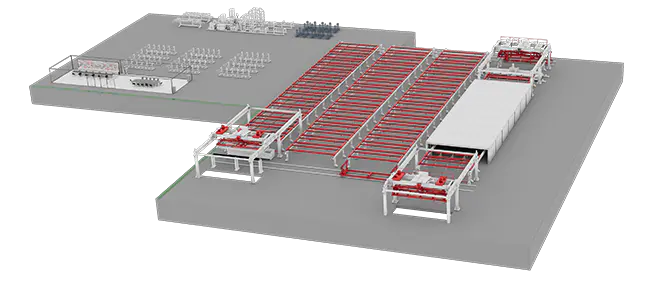

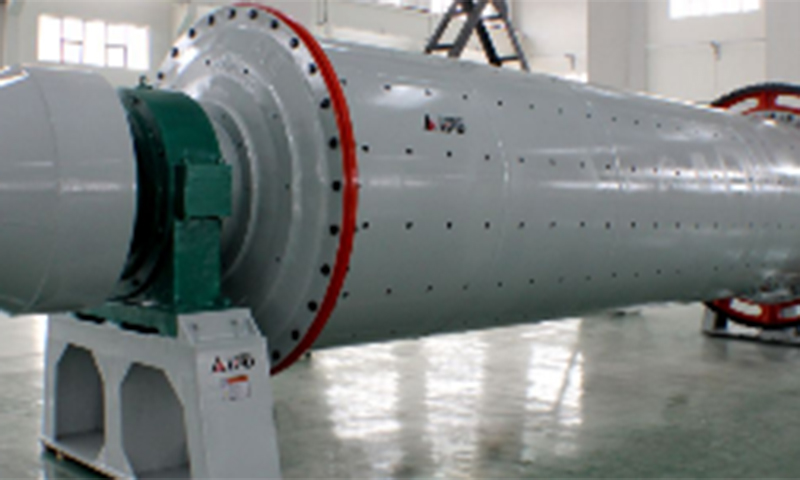

The production of AAC blocks adopts a highly automated production process. Modern AAC block machines usually use computer-controlled precision equipment, from the proportioning, mixing, molding to cutting of raw materials, to ensure that the size of each AAC block is accurate and meets the standards. This high-precision production method can reduce cutting losses during construction.

Unlike traditional concrete blocks or bricks, AAC blocks do not require a lot of cutting or trimming during construction. Traditional building materials often need to be cut to size on site, resulting in a large amount of scrap, and the high-precision production of AAC blocks reduces this problem. This means that the construction materials wasted during the construction process are significantly reduced, and the amount of construction waste generated is greatly reduced.

In large-scale construction projects, when using traditional building materials, it is often necessary to perform secondary processing of materials according to design requirements, which not only wastes a lot of raw materials, but also increases the difficulty of waste treatment. After using AAC blocks, due to their standardized and precise production characteristics, the remaining waste on the construction site is significantly reduced, reducing the generation of construction waste from the source.

3. Improve building durability and reduce maintenance waste

AAC blocks have high durability and corrosion resistance, which can effectively extend the service life of buildings. Its excellent physical properties make it difficult for buildings to crack, deform and other problems during long-term use, and also reduce the frequency of maintenance and renovation. This high durability means that buildings generate less waste during use, especially when renovating or replacing building components, AAC blocks reduce the need for demolition and reconstruction of buildings.

Usually, the aging and damage of traditional building materials will lead to large-scale renovation and demolition, which not only increases the resource consumption of buildings, but also generates a large amount of construction waste. The durability and stability of AAC blocks make it unnecessary to frequently renovate buildings during long-term use, reducing the generation of construction waste. Walls built with AAC blocks can remain in good condition for decades without frequent replacement and maintenance, thus avoiding the accumulation of construction waste.

4. Effectively reduce waste on the construction site

During the construction process, traditional building materials often generate a lot of waste due to improper human operation or restrictions on the construction environment. Traditional concrete, bricks, etc. often waste a lot of materials due to damage or misoperation during transportation, stacking and use. The production process and material characteristics of AAC blocks reduce the generation of waste during construction to a certain extent. Due to the good compressive strength and dimensional accuracy of AAC blocks, the probability of material breakage at the construction site is relatively low, reducing unnecessary waste.

AAC blocks usually adopt dry construction methods, and there is no need to use a large amount of cement mortar and other materials for bonding at the construction site, which also reduces the wastewater and waste residue generated during the construction process. In contrast, traditional building materials usually require more auxiliary materials during the construction process, such as cement mortar, masonry ash, etc. These auxiliary materials often leave a large amount of waste after the construction is completed, and the use of AAC blocks can reduce this phenomenon to a certain extent.

5. Waste Recycling and Circular Economy

AAC blocks themselves are recyclable. With the improvement of the awareness of resource recycling in the construction industry, more and more construction waste has begun to enter the circular economy system. Traditional construction waste is often difficult to recycle, while AAC blocks can be reused under certain conditions due to their light weight and environmental protection characteristics. Waste AAC blocks can be crushed and used to produce new building materials or used in other construction projects, which not only reduces the accumulation of waste, but also effectively saves raw materials.

This feature is in line with the current green development trend of the construction industry and supports the development of the circular economy in the construction industry. By recycling and reusing construction waste, AAC blocks not only reduce the generation of waste during the use of the building, but also provide the possibility for the recycling of waste during the building demolition stage, promoting the sustainable development of building materials.